Product Description:

SDQL series forced circulation pump is a horizontal, radially split, overhung-type axial flow pump. It is designed and manufactured according to GB/T 13008 Technical Specifications for Mixed and Axial Flow Pumps. It is a new type, high-efficiency, large-capacity, low-head series of forced circulation pump developed by our company by selecting an excellent hydraulic model based on advanced domestic and international structural characteristics. This series of pumps has a safe and reliable structure, stable operation, easy maintenance, stable hydraulic performance, high efficiency, wide range of use, and is a high-efficiency energy-saving product.

Parameter:

Capacity: 150~45000 m3/h

Head: 1.5~6.5m

Design pres.: 1.0MPa

Temp. range: -20~200ºC

Available in various materials.

For example, titanium materials (TA0, TA1, and TA2) are used.

Current max. diameter: DN2000 mm.

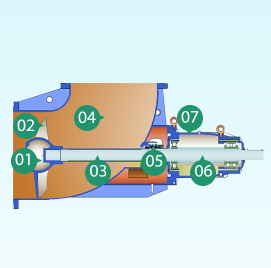

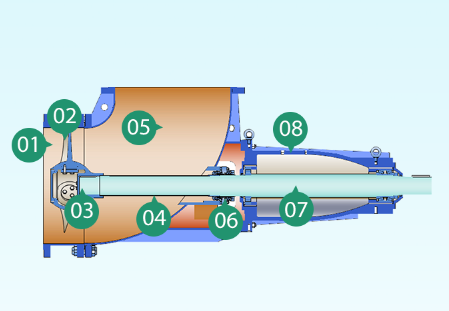

Cross-section Drawing

1. Reliable impeller fastening method, the impeller can be reversed.

2. 3D rapid prototyping of impeller. The blade model is highly accurate and can be adjusted according to user parameters. This allows for easy modification of the pump’s inlet and outlet directions.

3. Highly corrosion-resistant shaft sheath ensures that the shaft is not corroded.

4. The formed elbow is assembled by welding, resulting in smoother flow.

5. Equipped with cartridge double-end face mechanical seals or secondary packing seals. The shaft seal is more reliable.

6. High-strength alloy steel main shaft, with minimal deflection and smooth operation.

7. Long-span heavy duty bearing housing with excellent stability, high load-bearing capacity, and reliable operation.

1. The large-diameter pump features an independent impeller chamber, which facilitates the installation of the impeller.

2. The adjustable blades allow the blade angle to be modified according to user requirements, conveniently changing the direction of the pump’s inlet and outlet.

3. The reliable impeller fastening method allows the impeller to be reversible.

4. Highly corrosion-resistant shaft sleeve ensures that the shaft is not corroded.

5. The formed elbow is assembled by welding, resulting in smoother flow.

6. Equipped with cartridge double-end face mechanical seals or secondary packing seals. The shaft seal is more reliable.

7. High-strength alloy steel main shaft, with minimal deflection and smooth operation.

8. Long-span heavy duty bearing housing with excellent stability, high load-bearing capacity, and reliable operation.