BR Series Heavy Duty Petrochemical Process Pump

Product Description:

BR heavy duty petrochemical process pump is a horizontal, radially split, single, double or three-stage between-bearing centrifugal pump, as per Standard API 610, BB2 type. Its basic type is a single-stage structure, and the impeller is divided into double-suction and single-suction. This series of pumps is strictly designed according to the standard in terms of pump support, bearing arrangement, reserved connections, cooling and flushing, and chamber structure. Reasonable planning enhances the versatility of parts and reduces the number of spare parts types and maintenance time.

Parameter:

Standard: API 610 11th

API standard pump structure type: BB2

Capacity: 1~3300 m3/h

Head: 1~600m

Temp. range: -80~450℃

Design pres.:

For BR low-pressure design pumps: Single-stage pumps: 5.0MPa;Two-stage and three-stage

pumps: 11.0MPa

For BR high-pressure design pumps: Single-stage pumps: 11.0MPa; Two-stage and three-stage

pumps: 15.0MPa

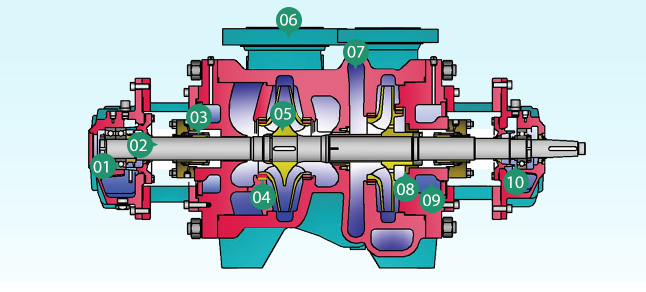

Cross-section Drawing:

1.B1R Structure

1. The bearing structure can be configured as rolling bearings, sliding bearings, or forced lubrication bearings based on power and rotational speed to ensure the safe and reliable operation of the pump.

2. The rigid shaft design features low deflection and stable operation. It is equipped with a conical shaft end that meets the requirements of API 610, making it convenient to install, disassemble, and maintain couplings, bearings, and seals.

3. API 682 standard seal chamber size,and different seal types can be configured according to requirements.

4. Both the pump cover and impeller are equipped with wear-resistant sealing rings. The clearance and hardness requirements of the sealing rings meet the standards of API 610, ensuring long service life and easy maintenance.

5. The impeller is available in both single-stage double-suction and single-stage single-suction designs. The double-suction structure offers excellent cavitation performance and eliminates hydraulic axial forces. It is suitable for various high- and low-pressure conditions and ensures the service life of the bearings.

6. Inlet and outlet flanges are designed according to GB.Also we will carry out ANS, HG, SH, DIN, EN standard on the basis of user requirements. The inlet and outlet can be up-in and up-out.

7. Design low pressure of BR type single-stage pump body is 5.0MPa,and design high pressure is11.0MPa. The double volute structure is adopted,which possesses excellent balanced radial force and has little influence on pump shaft and bearings.

8. The pump cover features a rigid design with high pressure-bearing capacity and reliability. It includes a water-cooling chamber that can reduce the temperature of the seal chamber during high-temperature condition, ensuring reliable operation of the mechanical seals.

9.Labyrinth dust-proof plate or mechanical oil seal can be selected.It can effectively prevent dust entering the housing to cause damage to the bearing, and also prevent leakage of lubricating oil, thus improve bearing life.

1. The bearing structure can be configured as rolling bearings, sliding bearings, or forced lubrication bearings based on power and rotational speed to ensure the safe and reliable operation of the pump.

2. The rigid shaft design features low deflection and stable operation. It is equipped with a conical shaft end that meets the requirements of API 610, making it convenient to install, disassemble, and maintain couplings, bearings, and seals.

3. API 682 standard seal chamber size,and different seal types can be configured according to requirements.

4. Both the pump cover and impeller are equipped with wear-resistant sealing rings. The clearance and hardness requirements of the sealing rings meet the standards of API 610, ensuring long service life and easy maintenance.

5. Impeller:first-stage double-suction and secondary-stage single-suction. This design offers excellent cavitation performance. The second-stage impeller uses a rear sealing ring and balance holes to balance the axial forces, eliminating hydraulic axial forces. It is suitable for various high- and low-pressure conditions and ensures the service life of the bearings.

6. Inlet and outlet flanges are designed according to GB.Also we will carry out ANS, HG, SH, DIN, EN standard on the basis of user requirements. The inlet and outlet can be up-in and up-out.

7. BR type two-stage structure.Design low pressure of BR type single-stage pump body is 11.0MPa, and design high pressure is 15.0MPa. Double volute structure is adopted,which possesses excellent balanced radial force and has little influence on pump shaft and bearings. The symmetric, space-transition flow passages reduce impact losses, thereby ensuring the inlet performance of the second-stage impeller and improving efficiency.

8. The inter-stage bushing structure is used between stages, effectively reducing inter-stage leakage and lowering the volumetric losses of the pump. This enhances the pump’s efficiency, maintains low pressure in the seal chamber, and ensures the safe operation of the seal.

9. The pump cover features a rigid design with high pressure-bearing capacity and reliability. It includes a water-cooling chamber that can reduce the temperature of the seal chamber during high-temperature condition, ensuring reliable operation of the mechanical seals.

10. Labyrinth dust-proof plate or mechanical oil seal can be selected.It can effectively prevent dust entering the housing to cause damage to the bearing, and also prevent leakage of lubricating oil, thus improve bearing life.

Copyright © 2018 JiangSu ShuangDa Pump Industry Co., Ltd. ICP:20037074-1

Powered by:INFOWUXI