BMA Petrochemical Process Pump

Product Description:

BMA petrochemical process pump is a horizontal, multi-stage, single or double suction at first stage, axially split, and between-bearing centrifugal pump, as per Standard API 610, BB3 type. The pump features a symmetrical impeller arrangement for self-balancing axial forces, reducing the failure rate of balancing mechanisms. Both the inlet and outlet are located at the bottom of the pump casing, allowing for easy disassembly and maintenance without the need to move pipelines.

Parameter:

Standard: API 610 11th

API standard pump structure type: BB3

Capacity: 20~2500 m3/h

Head: 70~1500m

Max. design pres.: 30MPa

Temp. range: -60~200ºC

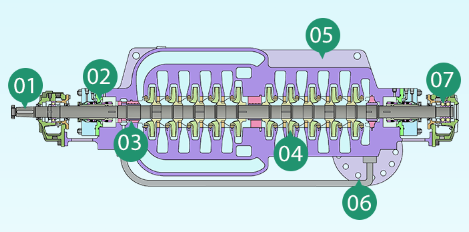

Cross-section Drawing:

1. Conical shaft end is convenient for assembly and disassembly of coupling. Site seal replacement, normal maintenance etc are also convenient.

2. API 682 standard seal chamber size,and different seal types can be configured according to working conditions and requirements.

3. Non-galling, high-hardness materials are used at all wear rings, inter-stage bushings, and throttle clearances. Higher hardness can be achieved through surface treatment, thus wear medium such as solid particles are conveyed.

4. Impeller heating assembly, and interference fit. The entire rotor has good rigidity and small deflection, which ensure running clearance and stable operation. The symmetrical arrangement of the impellers achieves self-balancing of axial forces.

5. Split type pump body is convenient for assembly. The double-volute structure balances radial forces, while the casing is rigorously designed to ensure strength and stiffness, enhancing reliability and stability of operation.

6. Pump inlet and outlet are at the bottom of pump body. It only needs to open upper cover of pump body in the course of maintenance and repair. There’s no need to move the pipeline, thus reduce maintenance time and improve maintenance efficiency.

7. Many kinds of bearing forms for different powers. The housing reserves various kinds of instrument interfaces for users to choose. Dust-proof structure is designed to prevent oil leaking and dust entering the housing.

Copyright © 2018 JiangSu ShuangDa Pump Industry Co., Ltd. ICP:20037074-1

Powered by:INFOWUXI