Product Description:

BMS petrochemical process pump is a horizontal, single-casing, radially split, multi-stage and between-bearing centrifugal pump, also known as a multi-stage single-casing sectional pump or ring-section pump, as per Standard API 610, BB4 type. The pump casing features a radial guide vane structure, which allows for the selection of either center-supported or foot-supported structures based on temperature requirements. The inlet and outlet can be flexibly arranged in multiple directions according to the user's needs. The first-stage impeller and the second-stage impeller are designed with different concepts: the first-stage focuses on the pump's cavitation performance, while the second-stage focuses on efficiency. The entire pump offers excellent cavitation performance and efficiency. The sealing system is designed in full accordance with API 682 Third Edition, Centrifugal and Rotary Pumps for Sealing Systems. It can be configured with various types of seal plans and flushing and cooling plans, making it suitable for a wide range of complex working conditions and applications. The balancing device employs a combination of a balance drum and a balance disc, which effectively balances the axial forces, reduces the load on the bearings, and extends bearing life. The bearings are divided into rolling bearings and sliding bearings, which can be selected according to the actual situation of the pump.

Parameter:

API standard pump structure type: BB4

Capacity: 3~900 m

Head: ~1800m

Max. design pres.: 27MPa

Temp. range: -80~210ºC

Application:

BMS pump is suitable for transferring all kinds of clean or mildly contaminated flammable, explosive, neutral and strongly corrosive medium, mainly used in cooling or heating systems, boiler feed water, condensate, descaling and general industrial applications.

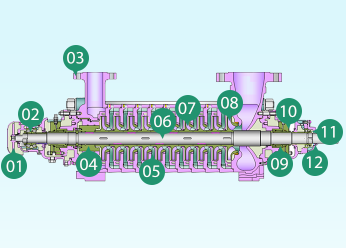

Cross-section Drawing

1. A fan is equipped to cool the bearing housing.

2. Tapered roller bearings are installed in a face-to-face arrangement, ensuring the bearing capacity and preventing overheating. Lubrication is provided by thin oil.

3. Foot mounted, inlet and outlet can have different options according to the user's needs, facilitating on-site installation.

4. The axial force is balanced using a combination of a balance drum and a balance drum sleeve. This structure is simple and provides effective balancing.

5. Non-galling, high-hardness materials are used at all wear rings, inter-stage bushings, and throttle clearances. Higher hardness can be achieved through surface treatment, thus wear medium such as solid particles are conveyed.

6. The positioning of the impeller shaft retains a certain installation clearance, which can reduce the deformation of the shaft as the temperature changes, and the entire rotor is dynamically balanced to ensure the stability of the rotor operation.

7. The secondary impeller has high efficiency index, and the whole series of products are highly efficient and energy-saving.

8. The first impeller is designed separately, with higher anti-corrosion performance.

9. API 682 standard seal chamber size,and different seal types can be configured according to working conditions and requirements.

10. The pump is available with either a cartridge single mechanical seal or a tandem double mechanical seal to achieve better sealing performance.

11. Radial cylindrical roller bearings are used to support radial loads.

12. Labyrinth dust-proof plate can be selected.It can effectively prevent dust entering the housing to cause damage to the bearing, and also prevent leakage of lubricating oil, thus improve bearing life.