Product Description:

BMRD(Z) petrochemical process pump is horizontal, double-casing, sectional, impeller is arranged in the same direction or back-to-back radial section, horizontal centerline support centrifugal multistage pump, as per Standard API 610, BB5 type.

This series of pump casing adopts radial guide vane structure, center support structure, and inlet and outlet can be up-in and up-out arrangement. The first-stage impeller and the second-stage impeller are designed with different concepts: the first-stage focuses on the pump's cavitation performance, while the second-stage focuses on efficiency, so that the whole pump has excellent cavitation performance and efficiency.

This series of pumps is strictly designed according to the standard in terms of pump support, bearing arrangement, reserved connections, cooling and flushing, chamber structure and material configuration.

It has excellent hydraulic performance, comprehensive performance range, and good anti-cavitation performance. Based on extensive experimental data and combined with hydraulic analysis software, the hydraulic performance has been optimized to reach the leading national level.

Parameter:

Standard: API 610 11th

API standard pump structure type: BB5

Capacity: 3~1000 m3/h

Head: ~4000m

Max. design pres.: 45MPa

Temp. range: -80~450ºC

Application: BMD(Z) pump is mainly applied in the transportation of petroleum, refined oil liquefied petroleum gas, light hydrocarbons, boiler feed water of various clean or flammable, explosive and toxic medium.

Cross-section Drawing

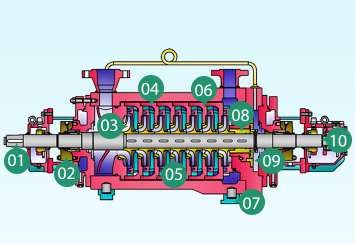

1.BMRD basic type structure drawing

1. Conical shaft end design: When the shaft diameter is larger than 60mm, the conical shaft end design is adopted, which is conducive to the installation and dismantling of couplings, bearings and seals.

2. Standard seal configuration: The chamber size is completely designed according to Standard API 682, and various types of seal flushing and cooling plans can be configured, or according to the user’s requirements.

3. Excellent cavitation performance: suction impeller design, excellent cavitation performance.

4. Easy inspection and maintenance: The core assembly is designed for complete extraction, enabling maintenance and inspection of the pump without the need to move the inlet and outlet piping.

5. Friction pair configuration: Both the pump casing and impeller are equipped with sealing rings. The clearance and hardness differences comply with Standard API 610, ensuring easy replacement of spare parts and extended service life.

6. High-temperature resistant design: At normal temperatures, the middle section sealing surface uses the O-ring for sealing. For high-temperature applications, a metal surface vs. metal surface design is employed.

7. Various bearing options: according to the shaft power size and different speeds, self-lubricating or forced lubrication bearing structure can be used.

8. Guiding arrangement: The casing is equipped with guide keys and locating pins. When conveying high-temperature medium, the pump extends towards the non-driven end without affecting the connection to the driver, ensuring reliable operation.

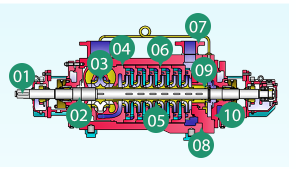

2.BMRD first stage double suction structure drawing

1. Conical shaft end design: When the shaft diameter is larger than 60mm, the conical shaft end design is adopted, which is conducive to the installation and dismantling of couplings, bearings and seals.

2. Standard seal configuration: The chamber size is completely designed according to Standard API 682, and various types of seal flushing and cooling plans can be configured, or according to the user’s requirements.

3.Excellent cavitation performance: The product features a suction-type, first-stage double-suction impeller design, with excellent cavitation performance.

4. Easy inspection and maintenance: The core assembly is designed for complete extraction, enabling maintenance and inspection of the pump without the need to move the inlet and outlet piping.

5. Friction pair configuration: Both the pump casing and impeller are equipped with sealing rings. The clearance and hardness differences comply with Standard API 610, ensuring easy replacement of spare parts and extended service life.

6. High-temperature resistant design: At normal temperatures, the middle section sealing surface uses the O-ring for sealing. For high-temperature applications, a metal surface vs. metal surface design is employed.

7. Inlet and outlet arrangement: The normal way is the up-in and up-out structure, or other arrangement according to the user’s requirements.

8. Guiding arrangement: The casing is equipped with guide keys and locating pins. When conveying high-temperature medium, the pump extends towards the non-driven end without affecting the connection to the driver, ensuring reliable operation.

9. Balancing structure: The pump employs a combined balance drum-disc-drum mechanism, which not only effectively prevents the occurrence of flashing but also significantly enhances the service life of the bearings and the overall operational stability.

10. Reliability assurance: The pump casing, pump cover, and other critical components are manufactured using forging processes. Additionally, a corrosion allowance of 3 mm is ensured, guaranteeing safe and stable operation of the pump under its design pressure.

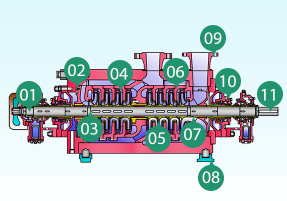

3.BMRDZ self-balancing structure drawing

1. Reliability assurance: The pump casing, pump cover, and other critical components are manufactured using forging processes. Additionally, a corrosion allowance of 3 mm is ensured, guaranteeing safe and stable operation of the pump under its design pressure.

2. Impeller positioning method: The impeller adopts a sliding assembly structure for serial positioning, which protects the shaft while enhancing its strength. This design also facilitates easy installation and removal.

3. Easy inspection and maintenance: The core assembly is designed for complete extraction, enabling maintenance and inspection of the pump without the need to move the inlet and outlet piping.

4. Impeller arrangement: The rotor impellers are symmetrically arranged, which allows for automatic balancing of axial forces without the need for a dedicated balancing mechanism. This design enhances the reliability of the product.

5. High-temperature resistant design: At normal temperatures, the middle section sealing surface uses the O-ring for sealing. For high-temperature applications, a metal surface vs. metal surface design is employed.

6. Excellent cavitation performance: The product features a suction-type impeller design, which ensures superior cavitation performance. To further enhance cavitation performance, the first-stage impeller can be optionally configured as a double-suction structure.

7. Guiding arrangement: The casing is equipped with guide keys and locating pins. When conveying high-temperature medium, the pump extends towards the non-driven end without affecting the connection to the driver, ensuring reliable operation.

8. Inlet and outlet arrangement: The normal way is the up-in and up-out structure, or other arrangement according to the user’s requirements.

9. Standard seal configuration: The chamber size is completely designed according to Standard API 682, and various types of seal flushing and cooling plans can be configured, or according to the user’s requirements.

10. Conical shaft end design: When the shaft diameter is larger than 60mm, the conical shaft end design is adopted, which is conducive to the installation and dismantling of couplings, bearings and seals.